10+ Available in Stock

-

Free Shipping on All Orders

Free Shipping on All Orders -

We will beat any price

1 Year Warranty -

Free shipping

Experts Aavaiable 7/24/365 -

30 days money-back

30 days money-back

Mitsubishi QC12B

Overview

The QC12B offers cutting-edge control for Mitsubishi's QC12B-series hydraulic shears, ensuring high-speed precision and enhanced safety during operations.

Key Features

Enhanced control for QC12B-series hydraulic shears

Closed-loop servo control for exact pressure and position

Multi-stage pressure adjustments for smooth operations

Customizable shear parameters and sequences

Built-in fault detection and diagnostics

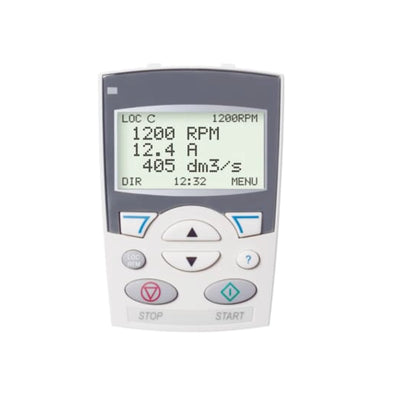

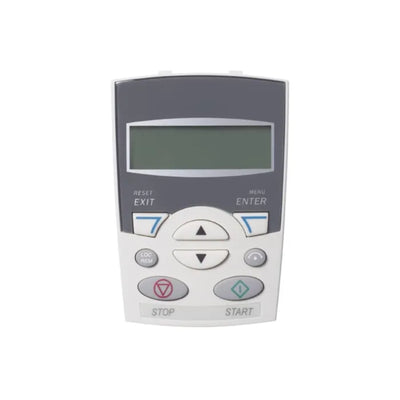

User-friendly interface with keypad and LED display

Safety interlock and emergency monitoring

Service counters and alerts

Technical Specifications

Control Method: Closed-loop hydraulic servo

Pressure Control: High-resolution, 0.1 MPa precision

Cutting Tab Adjustment: 10-step offset control

Cycle Time: Optimized for rapid shearing

Display: LED indicators, digital readout

I/O Capability: Multiple input/output for comprehensive integration

Safety: Emergency stop, interlock, fault protection

Mounting: Panel or cabinet installation

Operating Temperature: 0 to 40°C

Applications

Precise shearing for sheet metal fabrication

Fast cut cycles in production lines

Heavy-duty hydraulic presses and shears

Automotive body and panel processing

Industrial manufacturing with tight tolerances

Why Choose Mitsubishi QC12B?

Tailored control for superior QC12B shear efficiency

High-speed, precision hydraulic movement

Robust safety and diagnostic assistance

Simplified settings and maintenance tracking

Mitsubishi excellence for reliable industrial use

Order Now

Enhance your QC12B hydraulic shear with the Mitsubishi QC12B controller, crafted for precise, secure, and rapid metal cutting performance.

Browse our offerings for servo motors, drives, HMIs, cables, and more to find automation solutions suited for your needs.

Description

Mitsubishi QC12B

Overview

The QC12B offers cutting-edge control for Mitsubishi's QC12B-series hydraulic shears, ensuring high-speed precision and enhanced safety during operations.

Key Features

Enhanced control for QC12B-series hydraulic shears

Closed-loop servo control for exact pressure and position

Multi-stage pressure adjustments for smooth operations

Customizable shear parameters and sequences

Built-in fault detection and diagnostics

User-friendly interface with keypad and LED display

Safety interlock and emergency monitoring

Service counters and alerts

Technical Specifications

Control Method: Closed-loop hydraulic servo

Pressure Control: High-resolution, 0.1 MPa precision

Cutting Tab Adjustment: 10-step offset control

Cycle Time: Optimized for rapid shearing

Display: LED indicators, digital readout

I/O Capability: Multiple input/output for comprehensive integration

Safety: Emergency stop, interlock, fault protection

Mounting: Panel or cabinet installation

Operating Temperature: 0 to 40°C

Applications

Precise shearing for sheet metal fabrication

Fast cut cycles in production lines

Heavy-duty hydraulic presses and shears

Automotive body and panel processing

Industrial manufacturing with tight tolerances

Why Choose Mitsubishi QC12B?

Tailored control for superior QC12B shear efficiency

High-speed, precision hydraulic movement

Robust safety and diagnostic assistance

Simplified settings and maintenance tracking

Mitsubishi excellence for reliable industrial use

Order Now

Enhance your QC12B hydraulic shear with the Mitsubishi QC12B controller, crafted for precise, secure, and rapid metal cutting performance.

Browse our offerings for servo motors, drives, HMIs, cables, and more to find automation solutions suited for your needs.