What Is Allen-Bradley? A Comprehensive Overview

Allen-Bradley is a globally recognized name in the world of industrial automation and control systems. As a flagship brand of Rockwell Automation, Allen-Bradley has played a transformative role in modernizing factories and enabling smarter, safer, and more efficient industrial operations through advanced technologies and integrated solutions.

A Glimpse into Allen-Bradley’s Legacy

The story of Allen-Bradley began in 1903, when Dr. Stanton Allen and Lynde Bradley founded the company in Milwaukee, Wisconsin. Originally known as the Compression Rheostat Company, it was renamed Allen-Bradley in 1910 and quickly rose to prominence with innovative motor control products. Since its acquisition by Rockwell Automation in 1985, Allen-Bradley has evolved into a global leader in automation technology, maintaining a strong reputation for reliability and performance.

A Peek at Allen-Bradley’s Product Spectrum

Allen-Bradley offers a comprehensive portfolio that supports scalable and efficient automation:

-

Programmable Logic Controllers (PLCs): From micro PLCs to high-capacity systems like ControlLogix and CompactLogix, these controllers manage everything from machine-level to plant-wide operations.

-

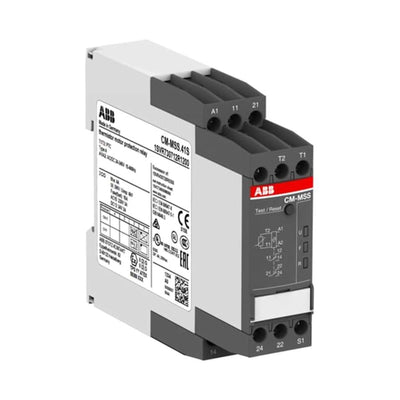

Motor Control Solutions: Including PowerFlex drives, soft starters, and motor protection technologies designed for precise control and energy efficiency.

-

Industrial Sensors and Switches: Featuring IO-Link-capable sensors for enhanced diagnostics and communication in automation systems.

-

Control Panel Components: Reliable push buttons, relays, terminal blocks, and safety devices ensure optimal machine performance.

-

Human-Machine Interfaces (HMIs): The PanelView HMI line provides responsive touchscreen control, remote monitoring, and data visualization.

-

Software & Tools: Studio 5000 software simplifies the programming and configuration of Allen-Bradley systems, enhancing productivity and minimizing setup time.

Innovations Driving Allen-Bradley

Allen-Bradley remains at the forefront of innovation with technologies that define modern manufacturing:

-

Smart Motor Control: Intelligent devices combine automation with real-time feedback for improved motor performance and preventive maintenance.

-

Advanced PLCs: ControlLogix systems offer high-speed processing, redundancy, and robust networking for complex applications.

-

Connected Sensors: IO-Link integration enables faster setup, remote diagnostics, and condition-based maintenance.

-

AR Maintenance Tools: Augmented reality allows technicians to visualize system data and perform guided troubleshooting.

-

Industrial IoT (IIoT): Embedded connectivity transforms machines into intelligent assets with real-time insights.

The Connected Enterprise: A Digital Future

Through Rockwell Automation’s Connected Enterprise vision, Allen-Bradley empowers industries to merge their physical operations with digital intelligence. Solutions like FactoryTalk and Integrated Architecture provide seamless data flow, advanced analytics, and cloud connectivity — reducing downtime, improving safety, and increasing productivity across the board.

Industrial Applications Across Key Sectors

Allen-Bradley’s solutions are trusted across industries that demand precision, compliance, and performance:

-

Manufacturing: High-speed automation, real-time quality control, and robotic integration.

-

Oil & Gas: Hazard-resistant systems for drilling, processing, and pipeline monitoring.

-

Automotive: Engine assembly, part inspection, and testing with synchronized automation.

-

Food & Beverage: Sanitary, traceable, and efficient processing equipment.

-

Life Sciences: Secure, validated systems for pharmaceutical production and packaging.

Allen-Bradley and Automation Ready Panels: A Strategic Partnership

In collaboration with Automation Ready Panels, Allen-Bradley delivers turnkey automation systems. These pre-configured panels are designed for quick deployment, minimal integration time, and compatibility with existing factory protocols. The result is reduced engineering costs and faster time to production.

The Future of Allen-Bradley: Leading Industry 4.0

As industries embrace Industry 4.0, Allen-Bradley continues to push boundaries through its commitment to digital transformation. From edge computing to AI-driven automation, the brand is shaping the next generation of smart manufacturing — making industrial operations more adaptive, intelligent, and connected.

Conclusion

With over a century of innovation, Allen-Bradley stands as a cornerstone of automation excellence. From legacy motor control devices to cutting-edge IIoT solutions, the brand has evolved to meet the ever-changing demands of global industries. As a driving force behind Rockwell Automation’s Connected Enterprise, Allen-Bradley continues to set the standard for the future of automation.